|

Model

|

HBC-60(F) |

| nominal cooling capacity |

kcal/h |

156176 |

| |

kw |

181.6 |

| input power |

kw |

57.28 |

| power supply |

3PH/380V/50HZ |

| refrigerant |

type |

R410a |

| |

type of control |

Expansion valve |

| compressor |

type |

hermetic scroll |

| |

power(kw) |

49.6 |

| condenser |

type |

finned copper tube + low noise outer rotor fan |

| |

cooling air flow(m3/h) |

60000 |

| evaporator |

type |

Shell and tube |

| |

chilled fluid flow(m3/h) |

31.31 |

| |

volume(L) |

750 |

| |

inlet and outlet pipe diameter (inch) |

3 |

| pump |

power (kw) |

4 |

| |

lift(m) |

22 |

| safety protection |

compressor over temperature, over current, high and low pressure, over temperature, flow switch, phase sequence, phase-missing, exhaust overheating, anti-freezing |

| weight |

kg |

1650 |

| dimension |

mm |

2700*2200*2050 |

Portable Water Chiller Features

1. The portable air cooled industrial chiller uses in small to medium cooling loads. Typically, available for 3 to 185 kW (0.85 to 52.6ons) with scroll compressor.

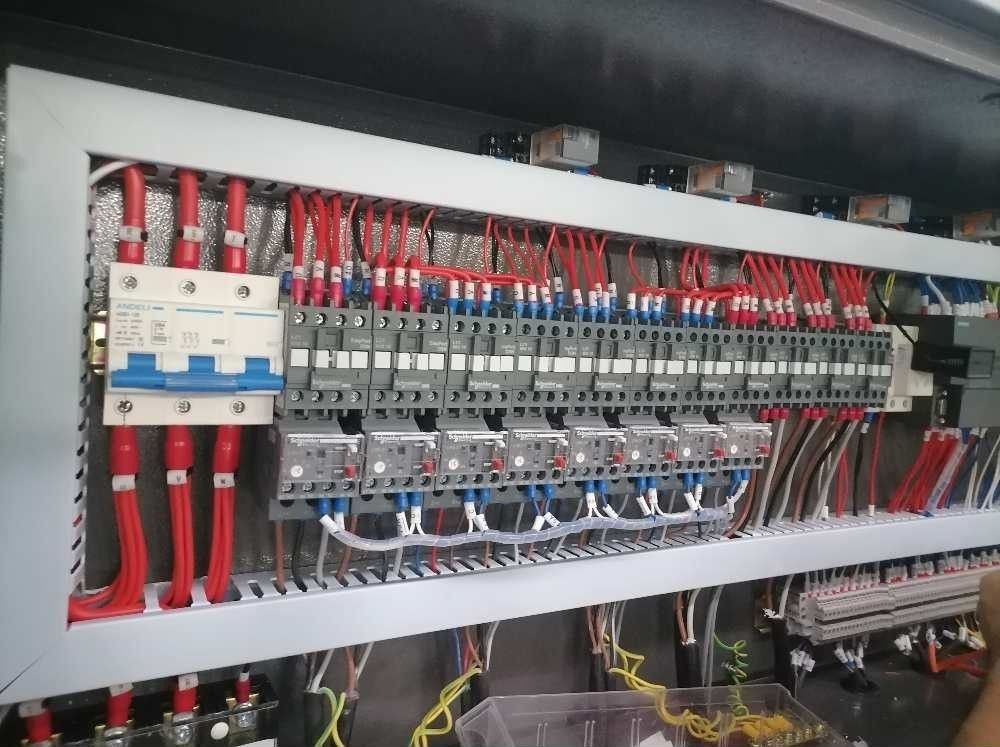

2. This 60 tons water chiller designed with Danfoss scroll compressor, efficient V-type condenser, Danfoss or Copeland thermostatic expansion valve, S.S 304 water tank and Schneider electric component.

3. The portable chillers are complete safety devices are equipped ,including compressor over temperature, over current, high and low pressure, over temperature, flow switch, etc. to ensure the chiller unit running stably with long service time.

4. Environment-friendly refrigerant R407C, R410A, R404A, R134a, etc, which is no harm to the ozone layer.

5. The industrial water chillers are designed with micro controller to ensure control accuracy. The interface is displayed in English, easy operation.

What we will do before chiller delivery ?

1. After industrial chiller assembly, we will charge nitrogen for pressure maintaining testing for 24hrs, to check whether there is leakage in the chiller cooling system.

2. Drain the nitrogen,vacuum the chiller system and set up parameters, then power on chiller and charge refrigerant at the same time.

3. Debug and test the chiller unit.

4. After the chiller commissioning, cleaning and labelling chiller unit, then have pre-delivery inspection before packing with plywood cases to to ensure that the chiller can be in good condition during transit.

How to select the model of the chiller ?

1. We need to know the heat load of your process or chiller cooling capacity.

2. Required water temperature, water pressure and flow rate.

3. Application and power supply in local.

4. Max. Ambient temperature in summer day.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!