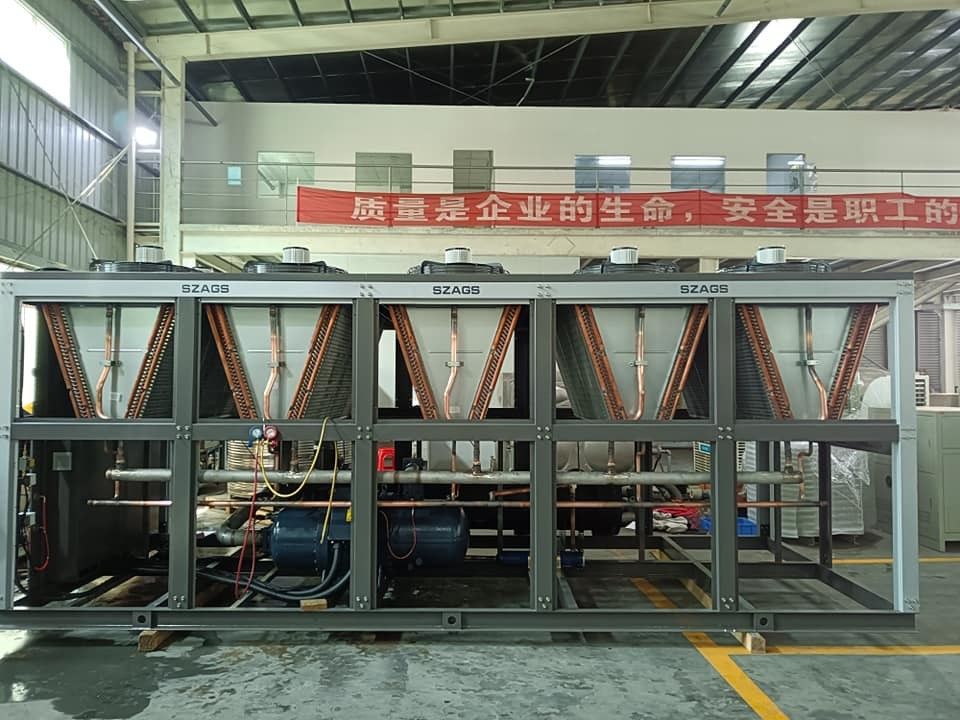

200HP Air-cooled Screw Type Industrial Chiller Screw Water Chiller For High Efficiency Cooling Solution

Technical Parameter of AGS-200ADH Air-cooled Screw Type Chiller

|

Model Parameter

|

AGS-200ADH |

| nominal cooling capacity |

kcal/h |

562268 |

| kw |

653.8 |

| input power |

kw |

214 |

| max running current |

A |

487.7 |

| power supply |

3PH 380V 50Hz |

| refrigerant |

type |

R407C |

| refrigerating circuit |

2 |

| weight(kg) |

140 |

| type of control |

thermostatic expansion valve |

| compressor |

type |

semi-hermetic screw |

| power(kw) |

89×2 |

| quantity |

2 |

| start-up mode |

Y-△ |

| capacity control |

0-25-50-75-100 |

| condenser |

type |

air cooled high-efficient inner threaded copper-tubing aluminum fin type |

| cooling air flow (m3/h) |

205000 |

| power(kw) |

36 |

| evaporator |

type |

shell and tube |

| quantity |

1 |

| chilled fluid flow (m3/h) |

112.5 |

| inlet and outlet pipe diameter (inch) |

5" |

| safety protection |

compressor over temperature protection, over load protection, high and low pressure protection, flow switch protection, reversed and lacking phase protection, anti-freezing protection. |

| dimension |

Length(mm) |

4200 |

| Width(mm) |

4400 |

| Height(mm) |

2383 |

| net weight |

kg |

4850 |

| running weight |

kg |

5120 |

Note: 1. Nominal cooling capacity is according to:

Inlet chilled fluid temperature: 17℃

Outlet chilled fluid temperature: 12℃

Inlet cooling air temperature: 35℃

Outlet cooling air temperature: 45℃

2. Working Range:

The temperature range of chilled fluid is from 5℃ to 35℃;

Temperature difference between inlet and outlet chilled fluid is from 3℃ to 8℃.

Temperature difference between inlet and outlet cooling air is from 8℃ to 12℃.

The machine can be used while the ambient temperature is below 40℃.

We reserve the right to modify the above dimensions or parameters without further notice.

Air-cooled screw chiller featurers

1.Adopting high-efficiency and energy-saving compressors of world class grade brands, high-quality condensers and evaporators, high cooling efficiency, stable performance, low noise and long service life.

2.The control system is adopting Siemens PLC controller and LCD touch screen , accurately controls the cooling capacity and cooling load of the unit in real time to achieve the best matching state, to ensure that the unit runs at the best efficiency and to reduce operating costs.

3.Screw compressor chiller capacity control can adopt four-stage (100%-75%-50%-25%), three-stage (100%-66%-33%) or stepless control system.

4.High-efficiency internally threaded copper pipes enhance the heat transfer effect are more energy efficient.

5.The machine is all made of oshell and tube evaporator and condenser, the welded structure is simple, sturdy structure, high quality, compact structure, long life and so on.

Advantages of SZAGS Air-cooled Screw Chillers:

1.Fast Response: Air-cooled screw chillers can quickly adjust cooling capacity to meet instantaneous load changes, enhancing system flexibility.

2.Environmentally Friendly: SZAGS air-cooled screw chillers use environmentally friendly refrigerants, reducing environmental impact and complying with modern eco-friendly requirements.

3.Easy Operation: User-friendly control systems simplify operation and monitoring, reducing reliance on specialized personnel.

4.High Durability: SZAGS Air-cooled screw chillers are made of high-quality materials and designs, offering a long service life and reducing replacement frequency.

5.Energy-Saving Options: SZAGS air-cooled screw chillers are designed with capacity control range 0-25-50-75-100%, which automatically adjusts operating speed based on actual load, further saving energy.

6.Suitable for Various Industrial Applications: SZASG Air-cooled screw chillers are widely used in chemical, food processing, pharmaceutical, and plastic manufacturing industries, demonstrating strong adaptability.

Support and Services:

The Portable Water Chiller product technical support and services include:

- Expert technical assistance for installation and operation

- Comprehensive user manuals and documentation

- Regular maintenance and servicing options

- Repairs and replacement parts

- Training and education on product features and capabilities

- 24/7 customer support for urgent issues

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!