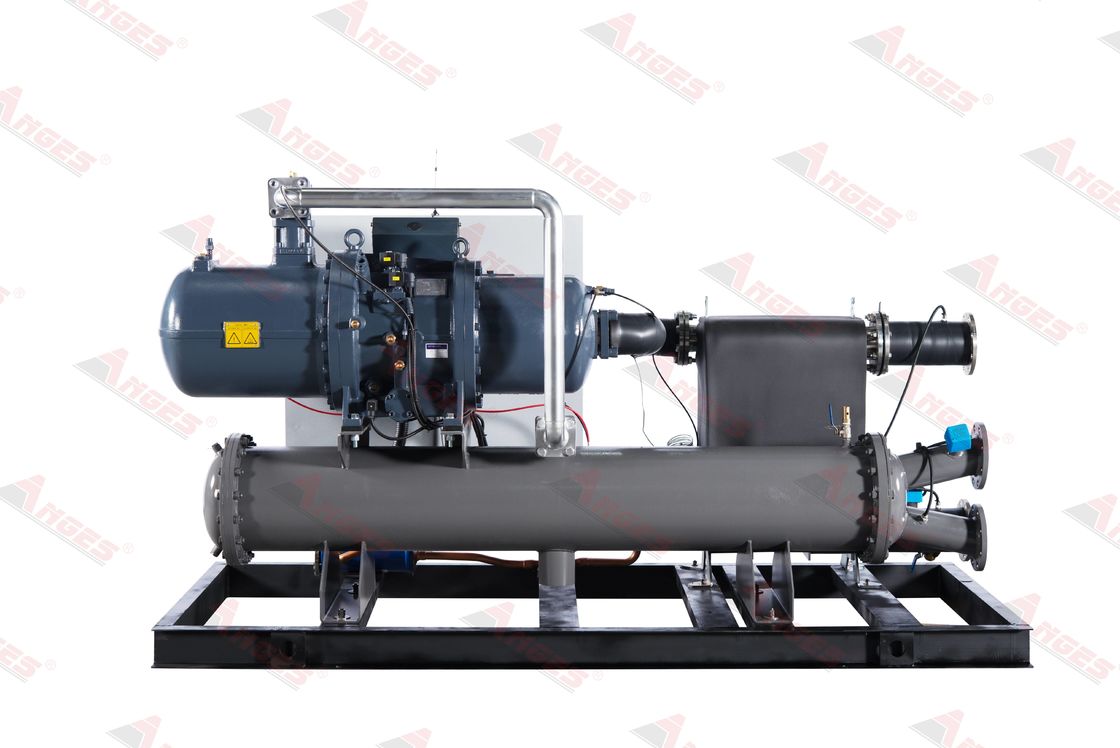

400RT Double Compressors Chiller Large Cooling Capacity Water-Cooled Screw Chiller For Beverage Industry

In the beverage manufacturing industry, water-cooled screw chillers primarily provide stable low-temperature cooling water for raw material cooling, fermentation temperature control, finished product cooling, and equipment heat dissipation, ensuring precise temperature control during production, fermentation, and filling processes, thereby enhancing production efficiency and ensuring product quality and taste.

This ANGES industrial water chiller can alternate operation automatically according to load change, to balancing the operating load of the compressor, greatly extending the working life of the chillers.

Specification

Technical Parameter of Industrial Air-cooled Chiller

|

Model

Parameter

|

AGS-360WDH |

| nominal cooling capacity |

kcal/h |

1189380 |

| |

kw |

1383 |

| input power |

kw |

273 |

| max running current |

A |

622.6 |

| power supply |

3PH 380V 50Hz |

| refrigerant |

type |

R22/R407C |

| |

refrigerating circuit |

2 |

| |

weight(kg) |

252 |

| |

type of control |

thermostatic expansion valve |

| compressor |

type |

semi-hermetic screw |

| |

power(kw) |

136.6×2 |

| |

quantity |

2 |

| |

start-up mode |

Y-△ |

| |

capacity control |

0-25-50-75-100 |

| condenser |

type |

shell and tube |

| |

cooling water flow (m3/h) |

285 |

| |

inlet and outlet pipe diameter (inch) |

6" |

| evaporator |

type |

shell and tube |

| |

chilled fluid flow (m3/h) |

237.9 |

| |

inlet and outlet pipe diameter (inch) |

8" |

| safety protection |

compressor over temperature protection, over load protection,high and low pressure protection, flow switch protection, reversed and lacking phase protection, anti-freezing protection, fusible plug |

| dimension |

mm |

4450*1580*2230 |

| net weight |

kg |

5380 |

| running weight |

kg |

5860 |

Note: The nominal cooling capacity is according to: Inlet chilled fluid temperature: 17℃,outlet chilled fluid temperature: 12℃.

Industrial chillers maintenance:

1.Coolant Inspection: Regularly check the coolant level and condition to ensure there are no contaminants or leaks.

2.Cleaning condenser and evaporator: Periodically clean these components to remove dust and dirt, ensuring efficient heat exchange.

3.Electrical system check: Inspect electrical connections and control systems for any looseness or damage to avoid eletrical failures.

4.Filter Replacement: Regularly replace clean filters to ensure smooth coolant flow and prevent blockages from impurities.

5.Monitoring Operating Parameters: Periodically record temperature, pressure, and flow to promptly identify any abnormal fluctuations.

6.Scheduled Maintenance: Arrange for professionals to conduct regular maintenance and check the operational status of chiller compressors and other key chiller components.

7.Frost Prevention Measures: In low-temperature enviroments, check the frost prevention system to avoid damage from frost buildup.

8.Ensure Good Ventilation: Make sure there is good ventilation around the equipment to lower operating temperatures and extend industrial chiller life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!