Industrial Chiller Screw Water Chiller Process Chiller Industrial Water Cooled Glycol Chiller Modular Water Chiller

Why do I need a industrial water chiller?

Industrial chillers are used for controlled cooling of products, mechanisms and machinery in a variety of industries. A chiller removes heat from the process water and transfers it to air via a heat exchanger.Industrial water chiller can keep your equipment at a safe operating temperature and cool your components during processes to ensure the highest quality final products and reduce production cycle time.

Application

Water cooled chiller widely used in different industries, precisely control the outlet water temperature from -40 ℃ to +30 ℃.

-

Plastics industry chiller

-

Electronic industry chiller

-

Electroplating industry chiller

-

Mechanical industry chiller

-

Building hvac air conditioner chiller

-

Vacuum coating chiller

-

Food industry chiller

-

Chemical fiber industry chiller

Which type of chiller are the most efficient?

Chillers can be air or water cooled, depending how the heat is rejected. Water-cooled screw chiller systems are especially used for large cooling loads, more compact, less noisy, have longer operating lives, they' re are more energy efficient than air cooled chillers, because they condense depending on the ambient temperature bulb temperature.

Screw water chiller capacity range is from 140kw to 760kw, water cooling temperature if adjustable 5 - 30 ℃. See our screw chiller catalogue for more details.

Water-cooled chiller systems have a cooling tower and use cooling water for heat dissipation which is perfect choice that use for process cooling for heat dissipation.This system includes item below.

Industrial Chiller Specification

|

Model

|

AGS-085WSH |

| nominal cooling capacity |

kcal/h |

273308 |

| |

kw |

317.8 |

| input power |

kw |

63.7 |

| max running current |

A |

145.2 |

| power supply |

3PH-380V-50HZ |

| refrigerant |

type |

R22 |

| |

type of control |

expansion valve |

| compressor |

type |

semi-hermetic screw |

| |

quantity |

1 |

| |

start-up mode |

Y-△ |

| |

capacity control |

0-25-50-75-100 |

| evaporator |

type |

shell and tube |

| |

chilled fluid flow (m3/h) |

54.7 |

| |

pipe diameter (inch) |

4 |

| condenser |

type |

shell and tube |

| |

cooling water flow (m3/h) |

66 |

| |

pipe diameter (inch) |

4 |

| safety protection |

compressor over temperature protection, over load protection, high and low pressure protection, flow switch protection, reversed and lacking phase protection, anti-freezing protection,fusible protection. |

| dimension |

mm |

3100*1050*1600 |

| net weight |

kg |

1560 |

| running weight |

kg |

1780 |

Benefit of industrial chiller applications

- Water-coold screw chillers could accurately provide the needed temperature for industrial manufacturing and largely improve efficiency.

- Accurate temperature control capability, the freezing temperature can be accurate to ±1℃, ensure the highest quality final products.

- Chillers can decrease equipment depreciation and degradation to cut down on operating expenditures.

- TheScrew compressors can achieve comparable part-load efficiencies, whether you run your chiller more often at part or full load, it will save energy.

Features of water-cooled water screw chillers

High-efficiency screw compressor with large cooling capacity from 120kw and 1600kw, it can achieve comparable part-load efficiencies, whether you run your chiller more often at part or full load to save energy.

Shell and tube evaporator, high-efficiency internally threaded copper tube, with low flow resistance and high efficiency.

The shell and tube condenser is low condensing temperature, good cooling effect, suitable for medium and large refrigeration system.It can run easily even in hot weather.

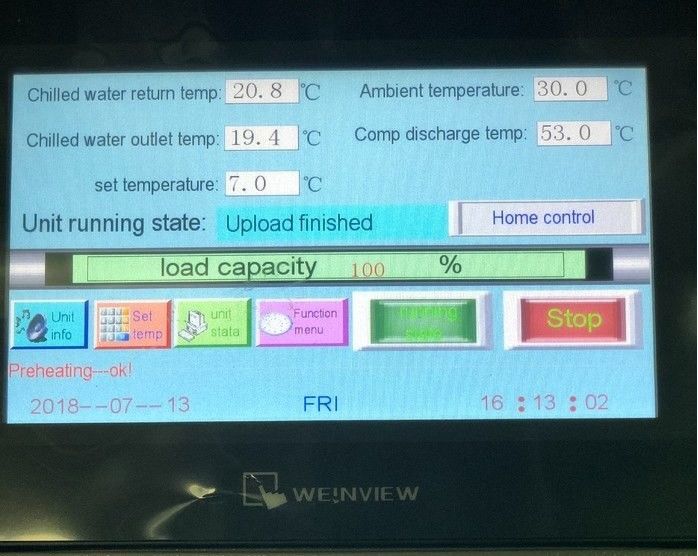

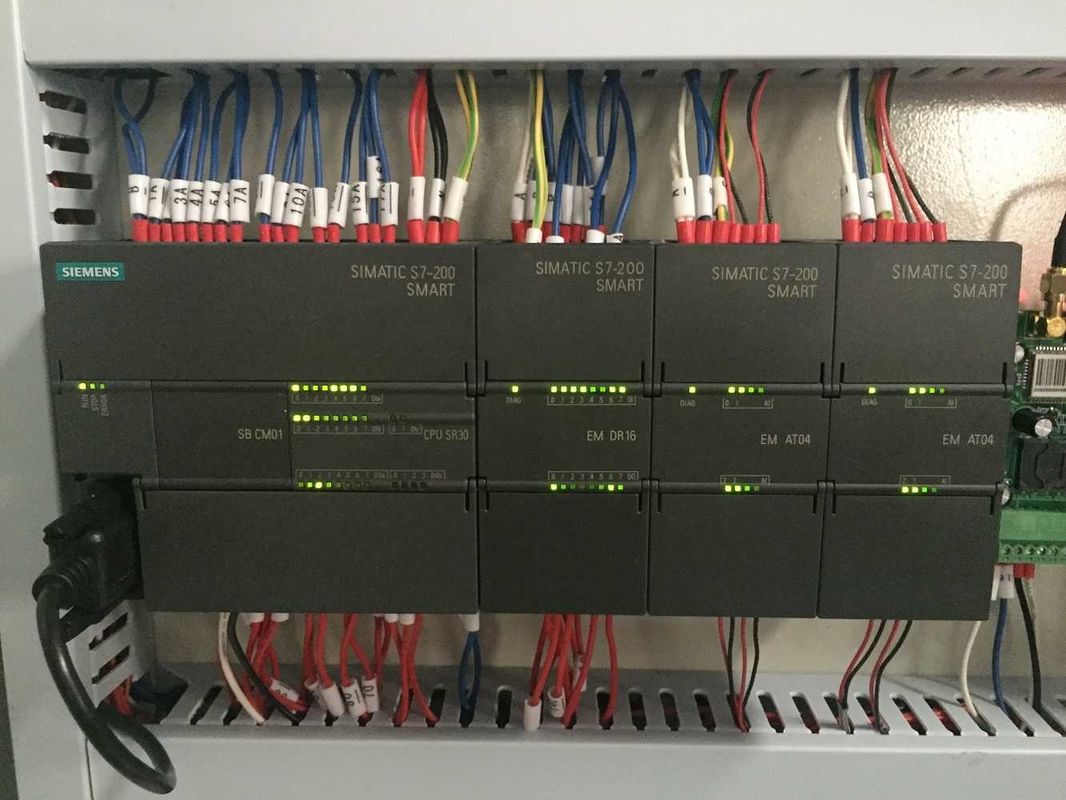

The control system is adopting Siemens PLC controller and LCD touch screen , accurately controls the cooling capacity and cooling load of the unit.

The chillers have multiple safety protection functions, such as phase sequence protection, flow protection, high and low voltage protection and overheating protection. High reliability, low failure rate, long service time.

The difference between Air-cooled chiller and Water-cooled chiller

An air-cooled chiller refers to a chiller system that uses the ambient air surrounding the condensing unit to cool and condense the refrigerant back into a liquid. In other words, the air cooled chillers use fans for chiller's refrigerant dissipate heat.

The most common types of water cooled chillers use water from an external cooling tower to cool the refrigerant in the condenser.They need to install cooling tower and cooling pump for operation. since they require a constant supply of water for cooling, they might not be suitable for locations with water shortages or restrictions.

Industrial water cooled Chiller installation

This water cooled screw chiller system including the items below:

Chiller

Cooling tower

Condenser cooling pump

process chilled water pump

- Install the chiller unit in a steady, ventilated and easy-installation place, avoid corrosion, pollution and weather-beaten.

- Choose a suitable cooling tower to match the chiller unit.

- Pipeline should be installed according to the dimension of the chiller. Do not reduction the size of the hose, or it will affect the refrigeration effect and increase the power consumption.

- The chiller unit must be installed more than 1 meter away from the wall, so that it is easy to install, maintain and adjust

How to select the model of the chiller ?

- We need to know the heat load of your process or chiller cooling capacity.

- Required water temperature, water pressure and flow rate.

- Application and power supply in local.

- Max. Ambient temperature in summer day

- Customized special specifications are acceptable. Contact us for more chiller Specification by number +86 13923791048.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!