Water Cooled Central Chiller 180ton Package Chiller Process Pump Water Screw Chiller Modular Water Cooled Screw Chiller

What is a central chiller?

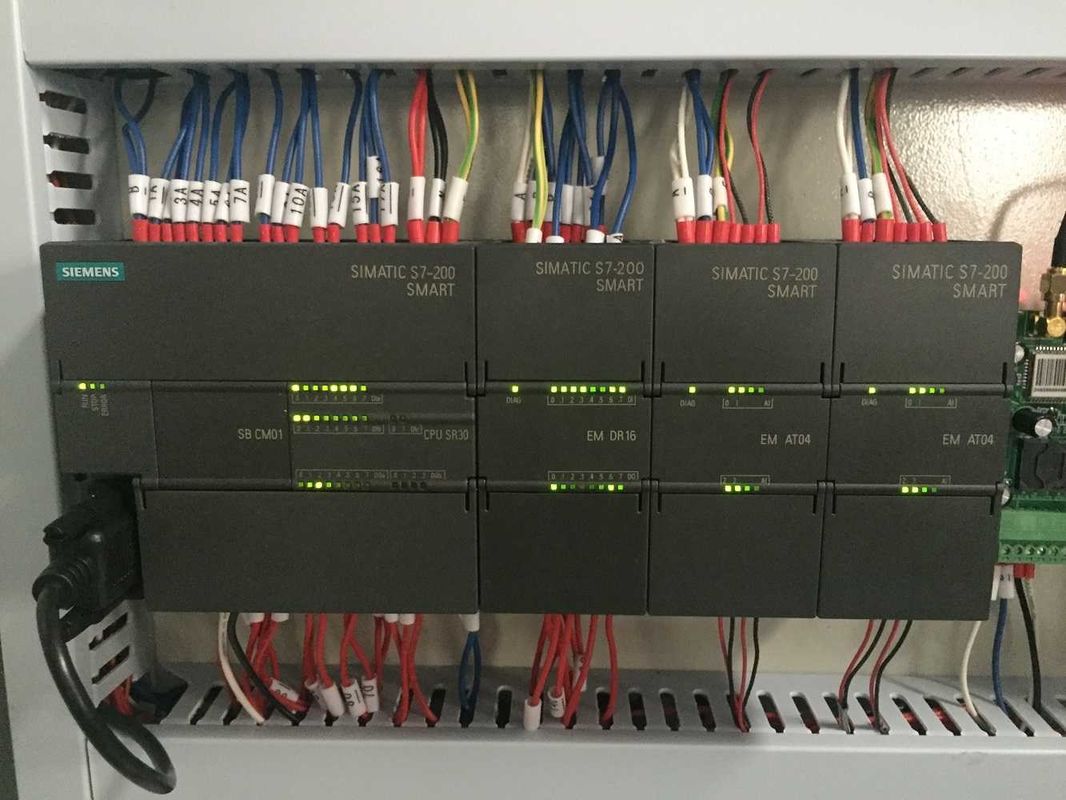

A central chiller is a complete cooling system including a chiller with complete process pumping system and reservoir in one package. Anges central water screw chiller system comes with pre-wired and pre-piped, all the items are mounted on the same frame, ready for quick and simple installation to save installation time and money.

With a process pump and internal chilled pump as standard, this package chiller system provides a wide range of options and configurations to suit any process need. All pumps are pre-wired to the control panel to save on costly field installation. All interconnecting piping, pumps, and reservoir are insulated to prevent condensation and improve the system cooling efficiency.

Water Cooled Screw Chiller Specification

| Item |

AGS-180WSHI |

| nominal cooling capacity |

kcal/h |

594518 |

| |

kw |

691.3 |

| input power |

kw |

170 |

| max running current |

A |

387.4 |

| power supply |

3PH-380V-50HZ |

| refrigerant |

type |

R22 |

| |

type of control |

expansion valve |

| compressor |

type |

semi-hermetic screw |

| |

Power(kw) |

136.3 |

| |

start-up mode |

Y-△ |

| |

capacity control |

0-25-50-75-100 |

| evaporator |

type |

shell and tube |

| |

chilled fluid flow (m3/h) |

118.9 |

| |

pipe diameter (inch) |

6 |

| condenser |

type |

shell and tube |

| |

cooling water flow (m3/h) |

148.6 |

| |

pipe diameter (inch) |

6 |

| safety protection |

compressor over temperature protection, over load protection, high and low pressure protection, flow switch protection, reversed and lacking phase protection, anti-freezing protection,fusible protection. |

| Tank |

L |

6000 |

| External circulation pump |

Power(kw) |

15 |

| |

Lift(m) |

24.9 |

| Internal circulation pump |

Power(kw) |

22 |

| |

Lift(m) |

32 |

| dimension |

mm |

4380*2750*2685 |

| net weight |

kg |

3550 |

| running weight |

kg |

9690 |

Water-cooled screw chiller

Water-cooled screw chiller systems are especially used for large cooling loads, they have a cooling tower for refrigerant heat dissipation that higher efficiency than air-cooled chillers which use fans for refrigerant heat dissipation.

Water-cooled chillers are more efficient because they condense depending on the ambient temperature bulb temperature, which is lower than the ambient dry bulb temperature.

Normally water-cooled chillers are cheaper and more efficient, with the disadvantage of high water consumption and cost more to install and maintain.

The difference between Air-cooled chiller and Water-cooled chiller

An air-cooled chiller refers to a chiller system that uses the ambient air surrounding the condensing unit to cool and condense the refrigerant back into a liquid. In other words, the air cooled chillers use fans for chiller's refrigerant dissipate heat, but the water-cooled needs to installa cooling tower for operation.Water-cooled chillers are more efficient with the disadvantage of having critical maintenance demands includeded water treatment, chiller condenser-tube cleaning, tower mechanical maintenance, and freeze protection.

Featurers of water cooled screw refrigeration chiller

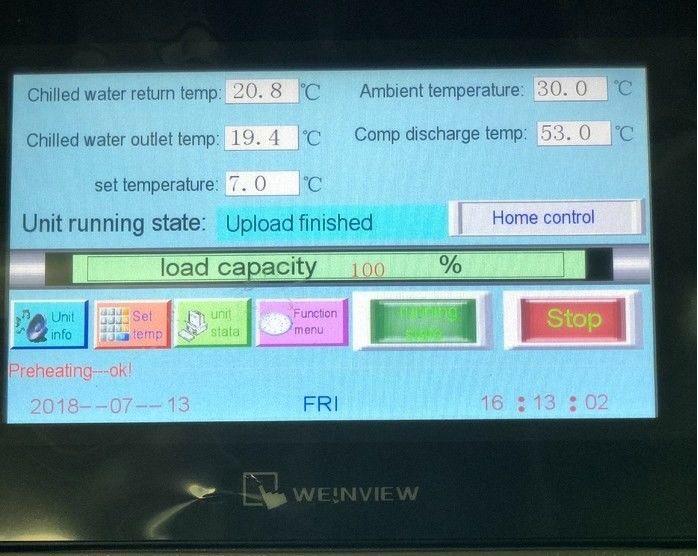

- Adjustable water temperature: Water cooled type chiller outptu chilled water from +5 to +30℃.Water temperature and flow rate can be designated and adjustable in control range.

- Stable performance: Anges packaged water cooled screw chiller equipted original famous brand Semi-hermetic screrw compressor adopted,feature sufficient cooling capacity,stable performance,and excellent quality. Smple structure, less moving parts, low failure rate, high safety factor, large cooling capacity.

- Power saving and energy saving: Screw chiller capacity control can be four (100%-75%-50%-25%) or three (100%-66%-33%) automatic adjustment ability, which can effectively save energy consumption according to the actual use of heat load, so as to effectively save energy.

- Long service life: Shell and tube evaporator and condenser, the welded structure is simple, sturdy structure, high quality, compact structure, long life and so on.

- Simple installation and operation: This 120ton screw compressor industrial water chiller system equipped famous brand water pump,with large flow,high efficiency and durability. Small size, easy to install, and simple to operate.

Why do I need a industrial water chiller?

Industrial chillers are used for controlled cooling of products, mechanisms and machinery in a variety of industries. A chiller removes heat from the process water and transfers it to air via a heat exchanger.Industrial water chiller can keep your equipment at a safe operating temperature and cool your components during processes to ensure the highest quality final products and reduce production cycle time.

Water chiller service from manufacturer

We are industrial chiller manufacturer, chiller service can be online support, video technical support, site service in some areas are available.

Site service will be done by our water chiller distributor, Indonesia, Philippines, Thailand, Singapore, Malaysia, Australia, United States, Israel, Egypt and so on.

- All the chillers are provided with 12 months free maintenance service.

- Provide technical explanation, chiller debugging support, technical training and chiller maintenance guidance.

- If necessary, after-sales engineers can be on-site service confirmed by both parties through communication .In some areas, local dealers can provide fast and convenient service.

- Provide the air chiller and water chiller required parts quickly to ensure the normal use of customers.If necessary, part of the wearing parts can be provided for backup after confirmation by both parties.

- Chiller maintenance service outside the warranty period, life-long tracking maintenance, cost price to provide equipment parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!