Industrial Refrigeration Process Chiller Water Cooled Screw Chiller Package Refrigeration Chiller Indoor Water Chiller cooling water chiller

Type of industrial chillers (Base on condenser type)

There' re two major types of industrial chillers in use today, air-cooled chillers, water-cooled chillers.Both air-cooled and water-cooled chillers are mostly the same, the main difference is in how the refrigerant is cooled(Condenser is different).

- Air-cooled chillers use ambient air (thru a cooling fan) to cool the refrigerant in cooing condenser and are a stand-alone units do not require any additional equipment to function.Easier for install and maintain than water-cooled systems.

- The most common types of water-cooled chillers use water from an external tower to cool the refrigerant in the condenser. Water-cooled chillers are generally more efficient than air-cooled chillers.

Water-cooled chiller systems includes items below.

Water-cooled chiller

Cooling tower

Cooling pump

Insulated water storage tank

Internal circulating pump and external process circulating pump

Water-cooled Industrial Chiller Specification

|

Model

|

AGS-360WDH |

| Nominal cooling capacity |

kcal/h |

1189380 |

| |

kw |

1383 |

| Input power |

kw |

273 |

| Max running current |

A |

622.6 |

| Power supply |

3PH-380V-50HZ |

| Refrigerant |

Type |

R22 |

| |

Type of control |

expansion valve |

| Compressor |

Type |

semi-hermetic screw |

| |

Power(kw) |

136.6×2 |

| |

Start-up mode |

Y-△ |

| |

Capacity control |

0-25-50-75-100 |

| Evaporator |

Type |

shell and tube |

| |

Chilled fluid flow (m3/h) |

237.9 |

| |

Pipe diameter (inch) |

8 |

| Condenser |

Type |

shell and tube |

| |

Cooling water flow (m3/h) |

285 |

| |

Pipe diameter (inch) |

6×2 |

| Safety protection |

compressor over temperature protection, over load protection, high and low pressure protection, flow switch protection, reversed and lacking phase protection, anti-freezing protection,fusible protection. |

| Dimension |

mm |

4450*1580*2230 |

| Net weight |

kg |

5380 |

| Running weight |

kg |

5860 |

Water-cooled screw chiller featurers

High-efficiency screw compressor with large cooling capacity from 120kw and 1600kw, it can achieve comparable part-load efficiencies, whether you run your chiller more often at part or full load to save energy.

Evaporator

Shell and tube evaporator, high-efficiency internally threaded copper tube, with low flow resistance and high efficiency.

The shell and tube condenser is low condensing temperature, good cooling effect, suitable for medium and large refrigeration system.It can run easily even in hot weather.

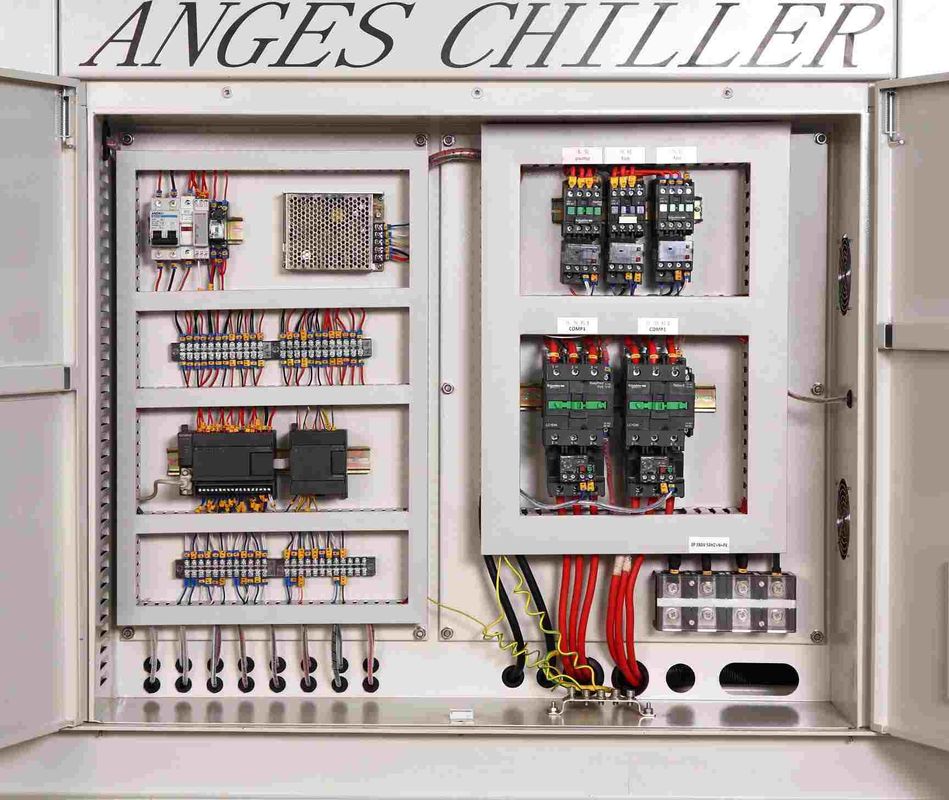

The control system is adopting Siemens PLC controller and LCD touch screen , accurately controls the cooling capacity and cooling load of the unit.

The chillers have multiple safety protection functions, such as phase sequence protection, flow protection, high and low voltage protection and overheating protection. High reliability, low failure rate, long service time.

Benefit of process chiller applications

- The ability to maintain constant and precise control of the process temperature.

- The cooling fluid can be delivered directly to the application heat source to increased production speed and ensure efficiency production

- Accurate temperature control capability, to ensure the highest quality final products.

- Water chiller systems prevent damage to heat-sensitive industrial components preventing undesirable repair downtime that might slow or even halt production altogether.

How to select the model of the chiller ?

- We need to know the heat load of your process or chiller cooling capacity.

- Required water temperature, water pressure and flow rate.

- Application and power supply in local.

- Max. Ambient temperature in summer day

- Customized special specifications are acceptable. Contact us for more chiller Specification by number +86 13923791048.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!