60 Ton Screw Water Chiller Central Chiller Air Cooled Chiller Screw Compressor Air Cooled Screw Chiller Rt

Air-cooled industrial screw chillers are from 120kw to 760 kW (34 to 216tons) which used for heavy-duty industrial applications, generally require less space than a water-cooled chiller. You can normally install the air cooled chiller on a rooftop, in a parking lot or anywhere else you have open space available.

Specification

|

Model

|

AGS-060ASH |

| nominal cooling capacity |

kcal/h |

151188 |

| |

kw |

175.8 |

| input power |

kw |

61 |

| Max. Running current |

A |

138.3 |

| power supply |

3PH~380V/50HZ |

| refrigerant |

type |

R22 |

| |

refrigerating circuit |

1 |

| |

type of control |

thermostatic expansion valve |

| compressor |

type |

semi-hermetic screw |

| |

quantity |

1 |

| |

Power |

51.7 |

| |

start-up mode |

Y-△ |

| |

capacity control |

0-25-50-75-100 |

| condenser |

type |

air cooled type finned copper tube |

| |

cooling air flow (m3/h) |

63000 |

| |

power(kw) |

9 |

| evaporator |

type |

shell and tube |

| |

quantity |

1 |

| |

chilled fluid flow (m3/h) |

30.2 |

| |

inlet and outlet pipe diameter (inch) |

3 |

| safety protection |

compressor over temperature, unit overload, high and low pressure, flow switch, phase sequence, phase-missing, anti-freezing |

| net weight |

kg |

1930 |

| Dimension |

mm |

2400*2000*2180 |

Nominal cooling capacity is according to:

Inlet chilled fluid temperature:17℃, Outlet chilled fluid temperature: 12℃.

Inlet cooling air temperature: 30℃, Outlet cooling air temperature:35℃.

The temperature range of chilled fluid is from 5℃ to 30℃.

How does a central chiller water screw chiller working in Plastic and Rubber industry?

A central chiller is referred to as any chiller used to cool several processes.A central chiller used for Plastic and Rubber industry moulding machine is easy to install and use by using one unit chiller to provide cold water to several production lines. Input certain water into an external tank, through the chiller cooling system the water would be cooled down, then the external water pump would pump out this cooled water into each moulds of the machine.The hot water from the moulds would go back into the water tank for a new cooling cycle.

Screw type air cooled chiller features

1. Screw compressor chiller is smple structure, less moving parts, low failure rate, high safety factor, large cooling capacity

2. The screw chiller capacity control can be four (100%-75%-50%-25%) or three (100%-66%-33%) automatic adjustment ability, which can effectively save energy consumption according to the actual use of heat load.

3. There is no need to design and install cooling tower, cooling water pump and related pipelines, the system is simple in design, convenient in construction and fast in installation.

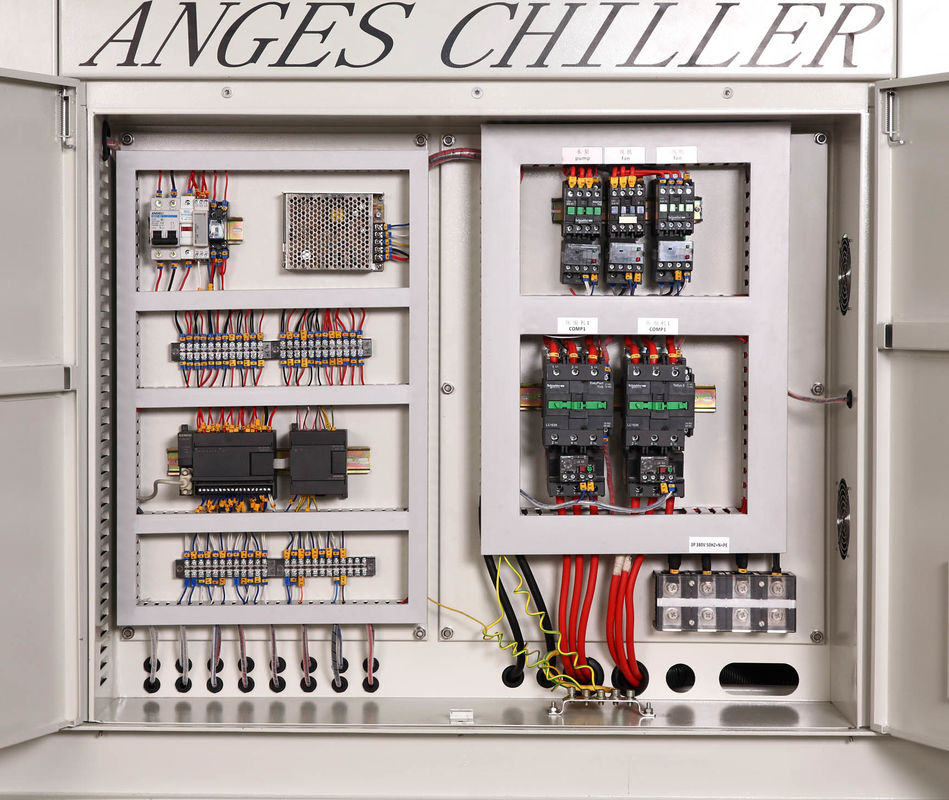

4. The screw central chiller control system adopts PLC program controller, the man-machine community is equipped with screen touch screen, the interface is simple and generous, and the operation is intuitive and simple.

5.Air-cooled screw type chiller is stable and reliable, the energy efficiency ratio is high, and the noise is low.

Installation Diagram

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!